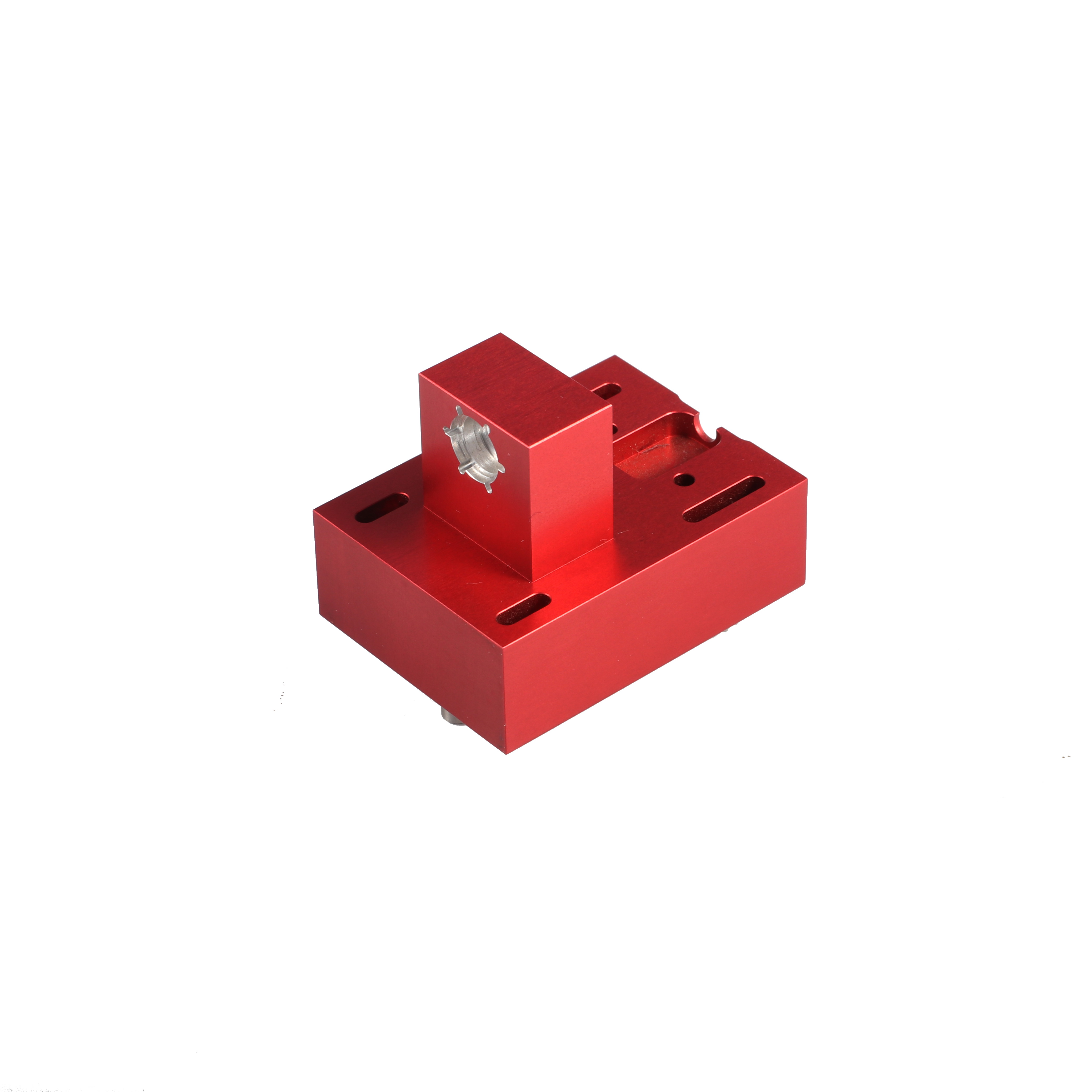

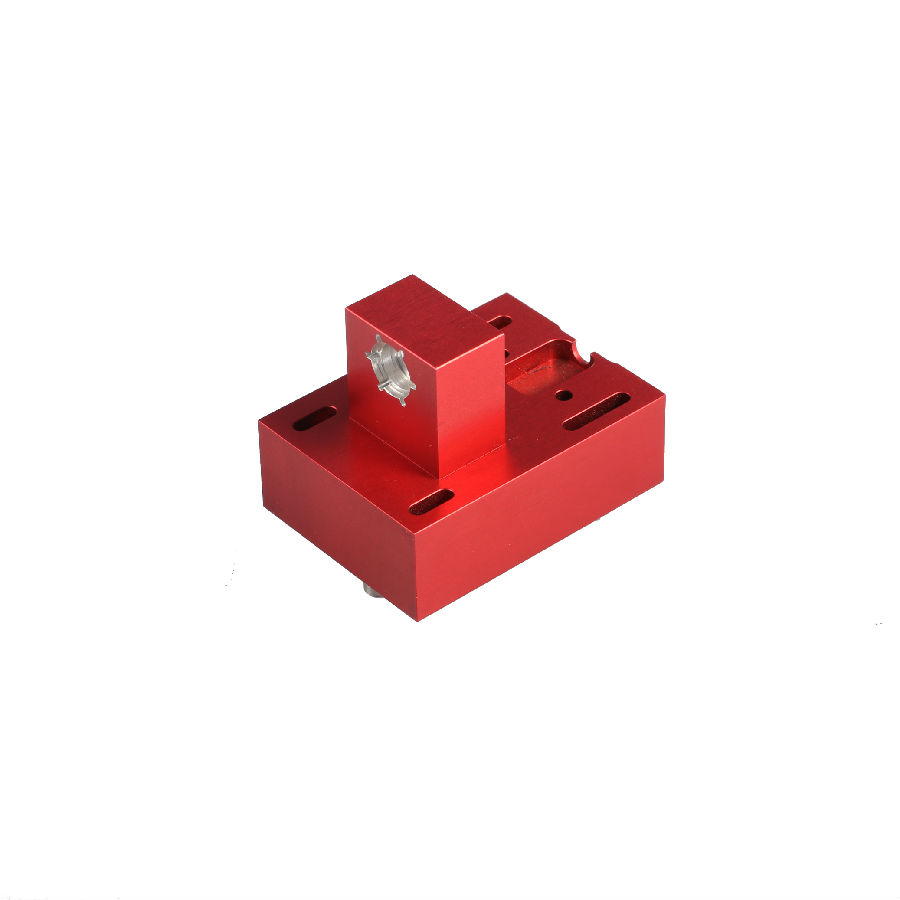

It is finished by CNC precision processing, and the product is colored and oxidized before secondary processing to ensure that there is no oxide layer in the middle of the internal thread and ensure that the functionality of the product is not affected.

It is finished by CNC precision processing. After the product is colored and oxidized, the secondary processing is carried out to ensure that there is no oxide layer in the middle of the internal thread and ensure that the functionality of the product is not affected. There are many options for the surface treatment process of aluminum. The functional ones include hard oxidation and conductive oxidation, and the outward appearances include chlorate, natural anode, black anode, sandblasting, coloring, and colorful.

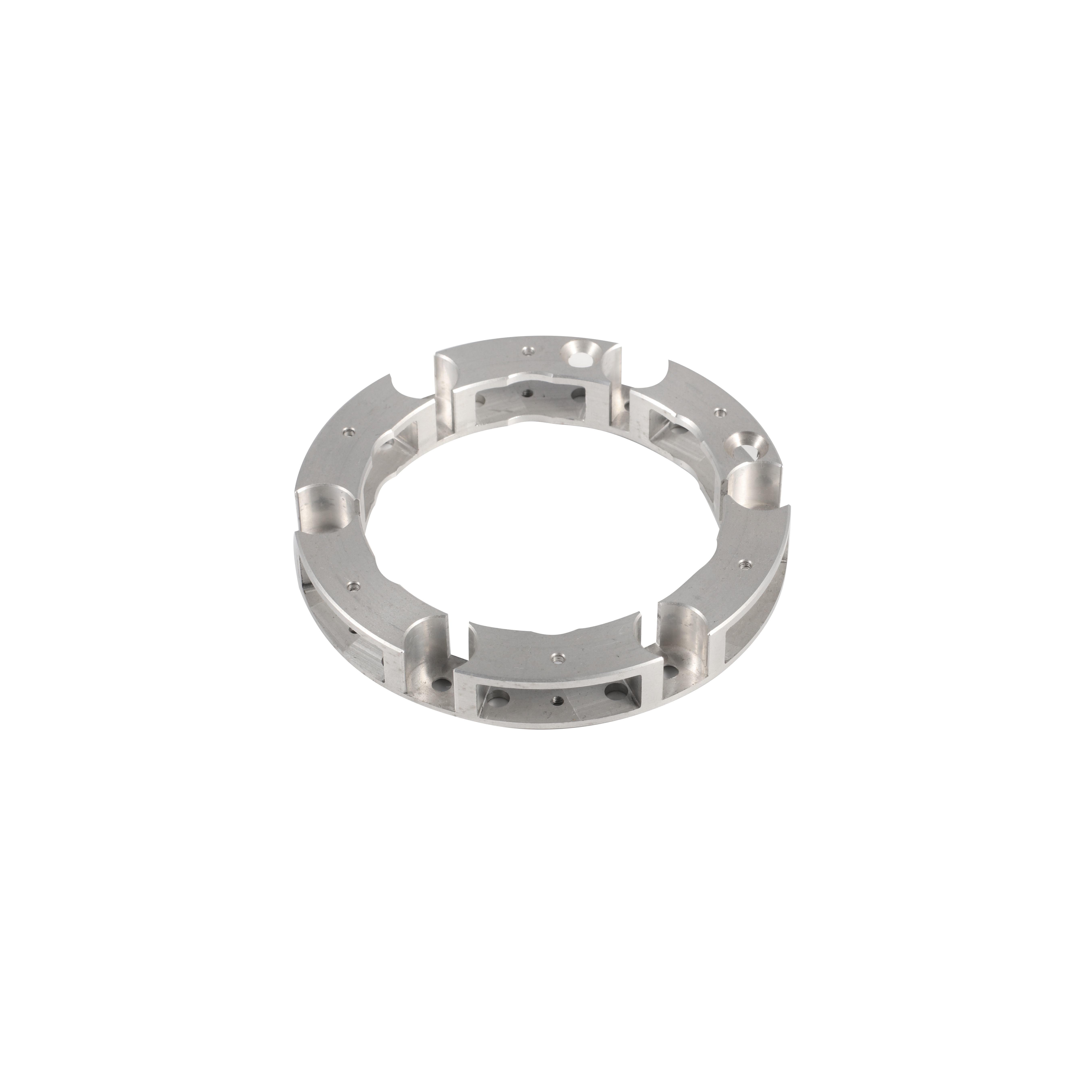

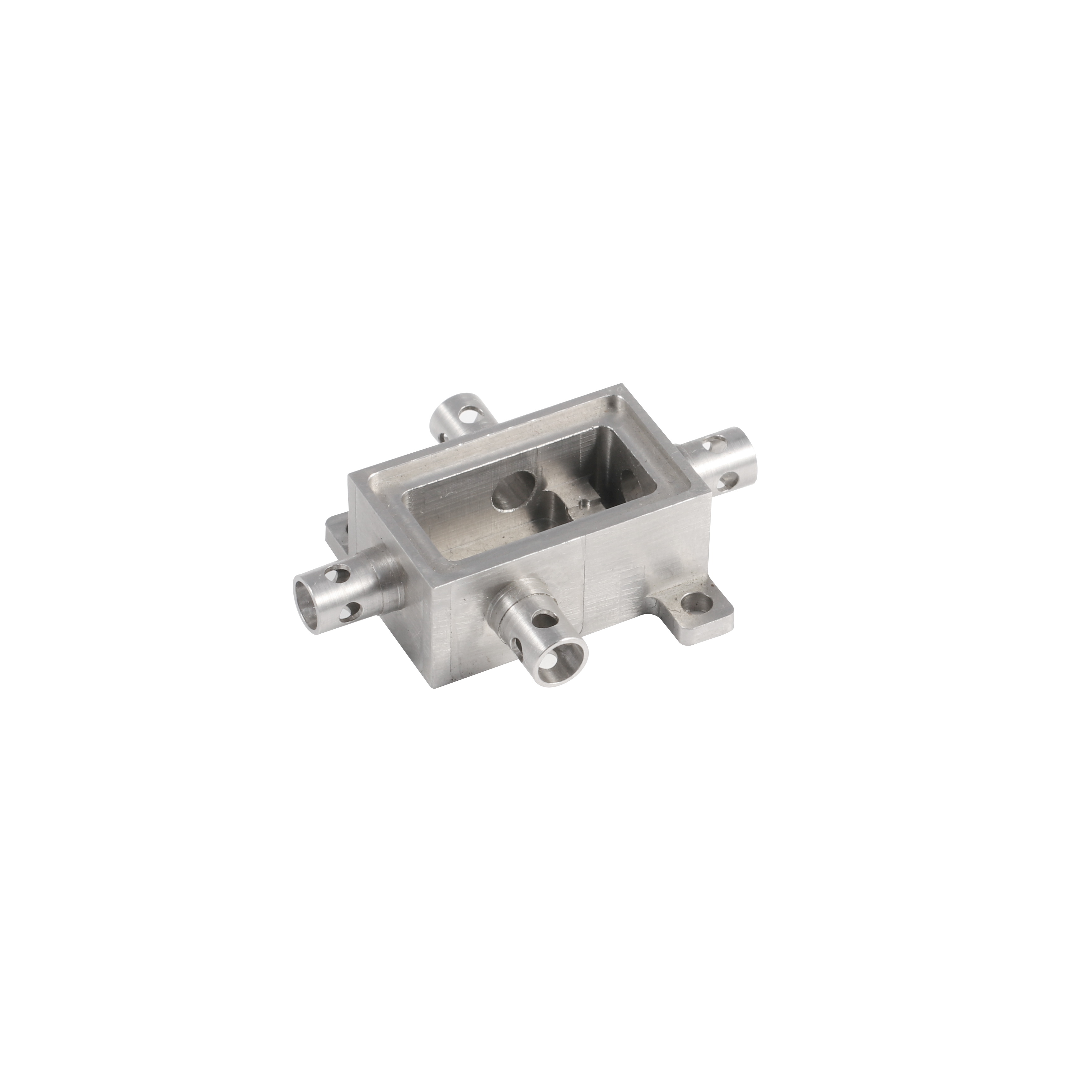

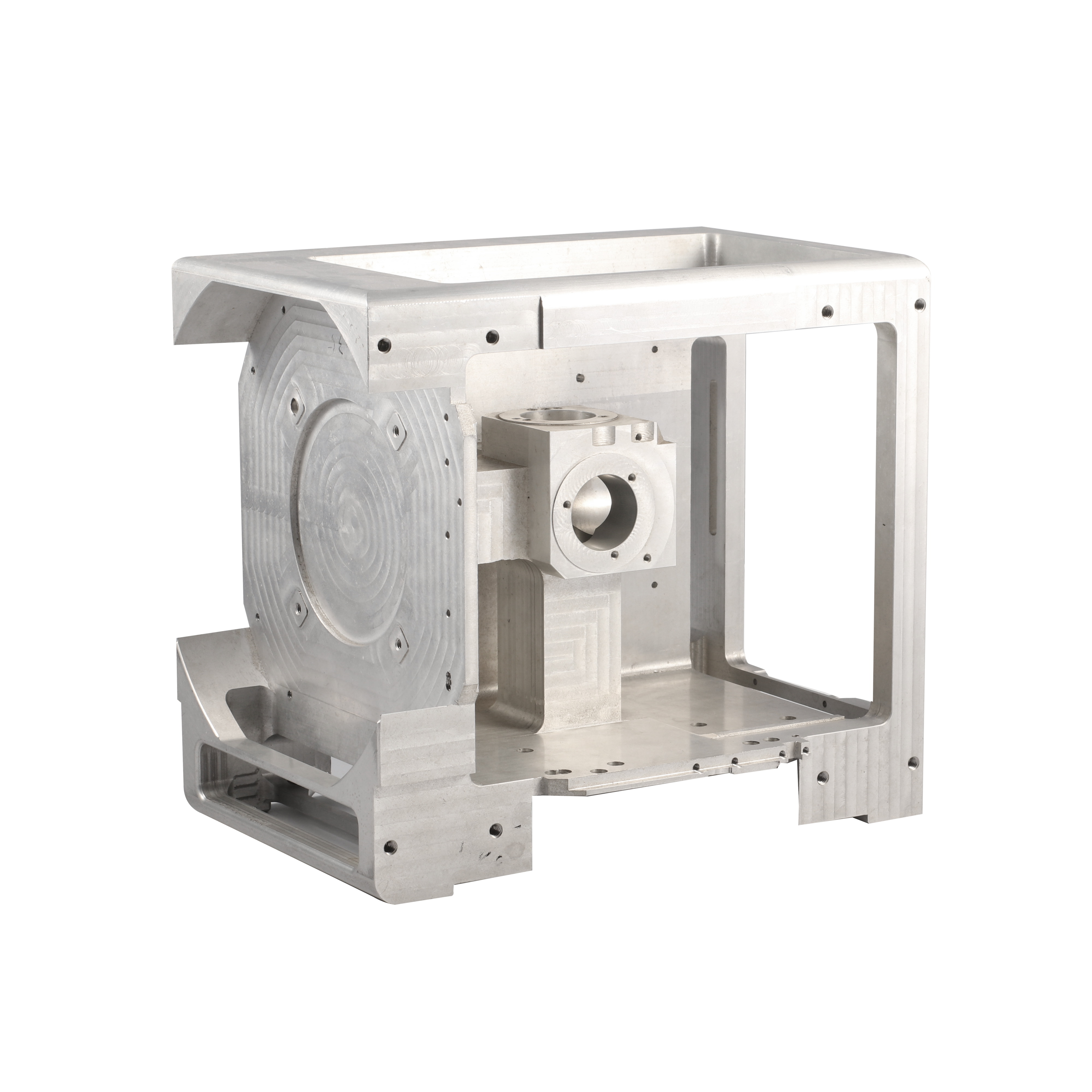

Component features:

| Processing technology | CNC Precision machining |

| Material Mode | AL6061-T6 |

| Sample/production lead time | 7/15 working days |

| Product processing accuracy | min-0.005mm |

| Product processing | CNC lathe - surface treatment - full inspection - packaging - delivery |

| Product standard | 500mm*1560mm |

| Surface treatment | Red anode |

| Packing standard | Copy paper +pearl wool +carton box or according to customer requirements |

| Related testing equipment | Two - dimensional image meter, three - coordinate measuring instrument, thread gauge, two - dimensional height meter, etc |

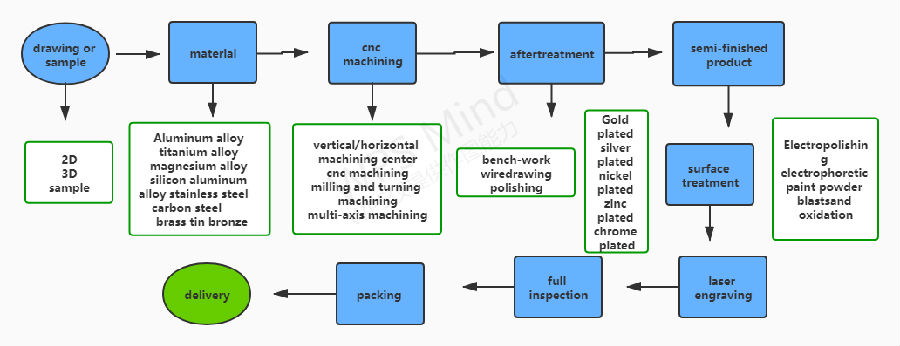

SWKD has focused on CNC precision machining for many years. The processed materials are very wide. The conventional processing materials include aluminum alloy materials, carbon steel materials, copper materials, stainless steel, etc., and special materials include mold steel, iron-nickel alloy, and high silicon. Aluminum, Kovar alloy, titanium alloy, etc., products are widely used in medical equipment industry, drone industry, automation equipment industry, optical communication industry, etc.