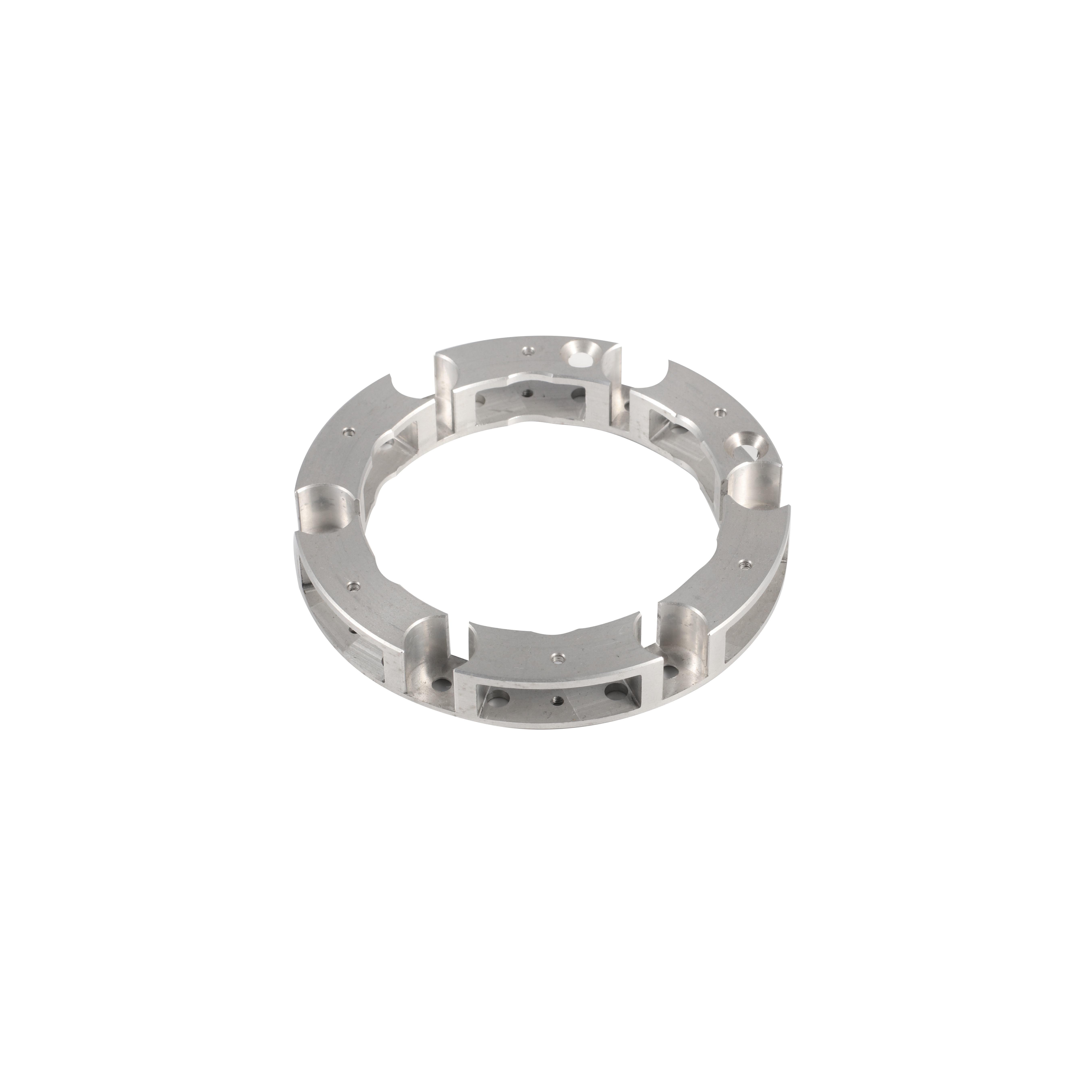

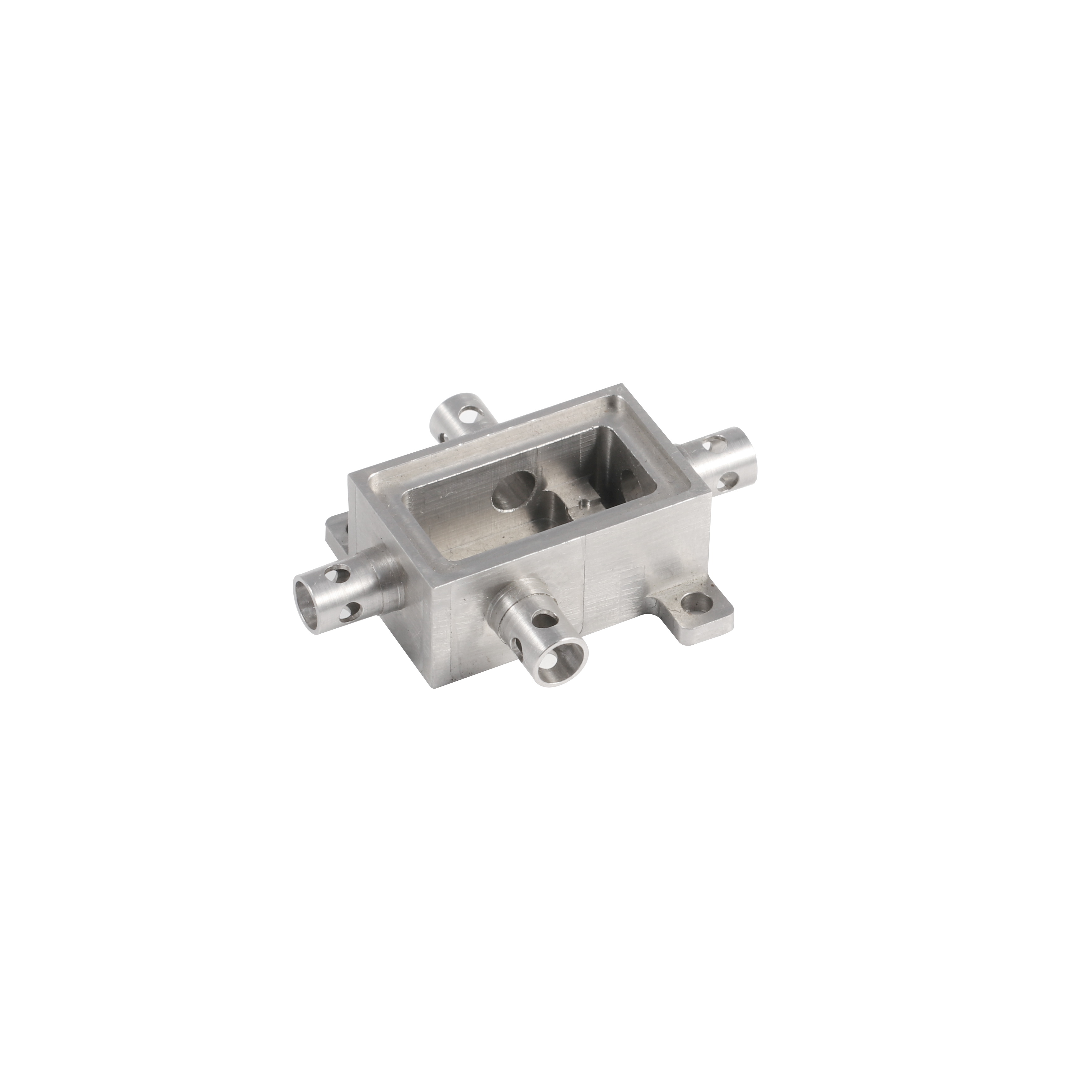

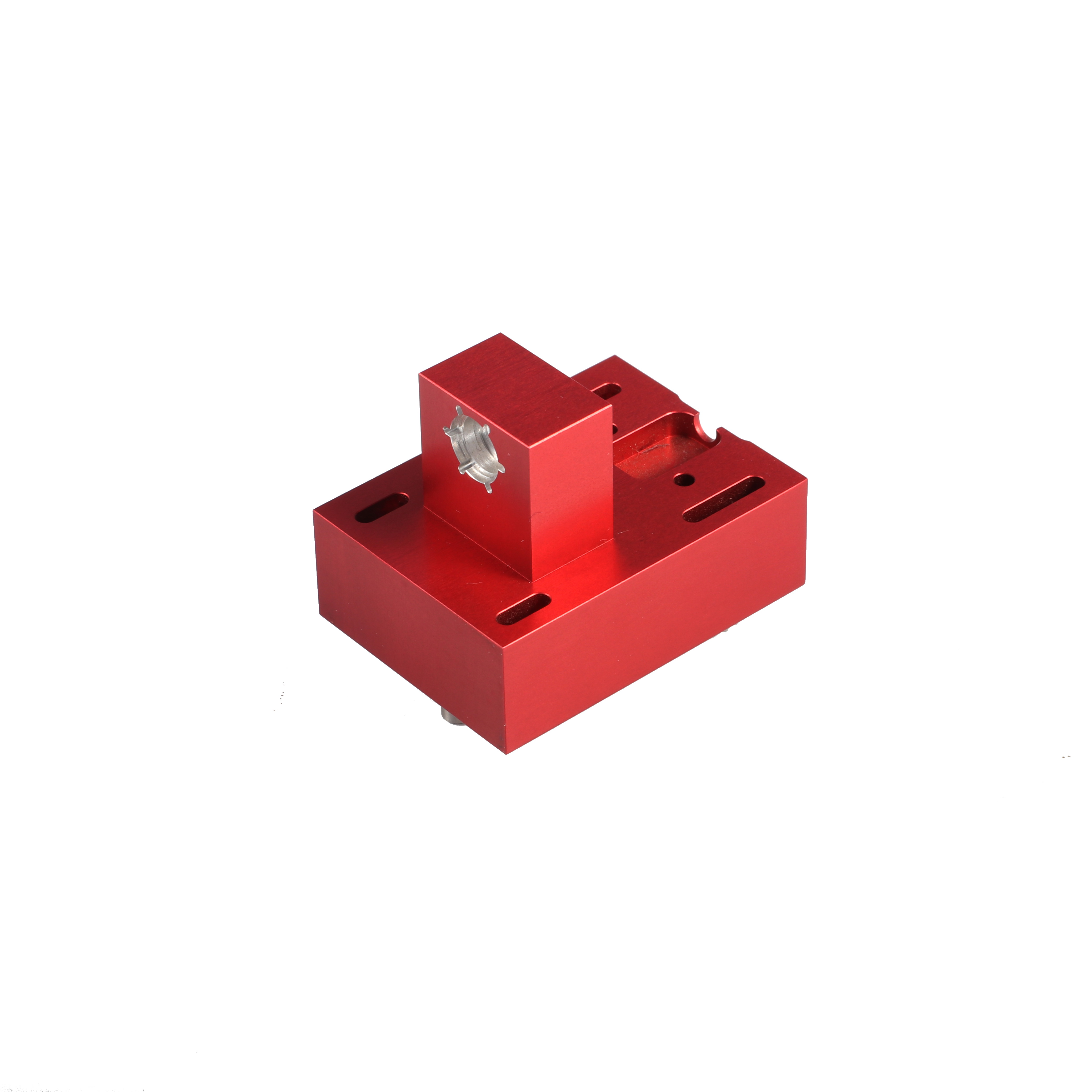

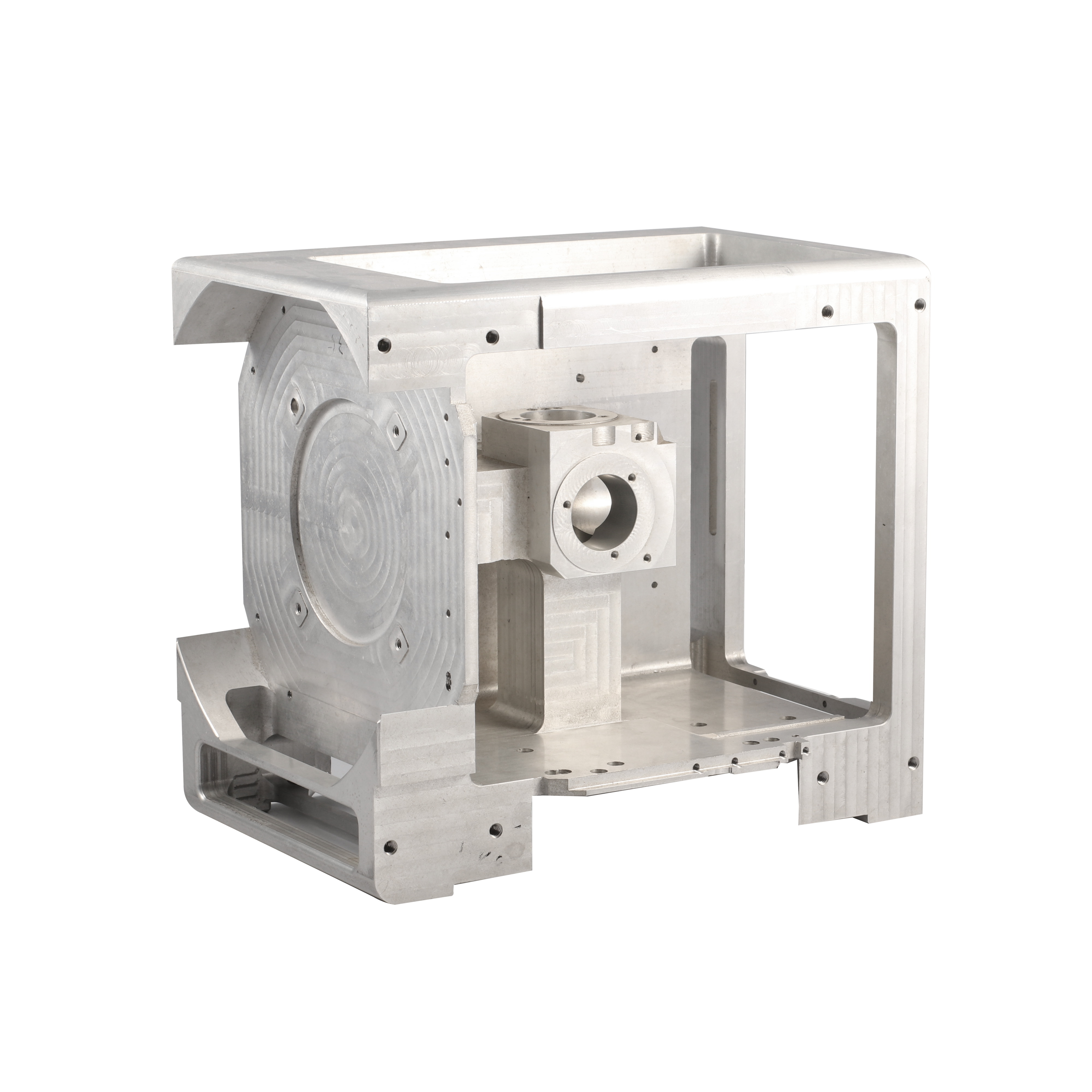

In the CNC processing of optical communication equipment parts,main material are high silicon aluminum,

stainless steel, oxygen free copper, aluminum alloy, cutting alloy, appearance requirements are high,

processing details need to be strictly controlled.

Component features:

Processing technology | CNC precision machining |

Material Mode | high silicone aluminum |

Sample/production lead time | 7/15 working days |

Product processing accuracy | min-0.02mm |

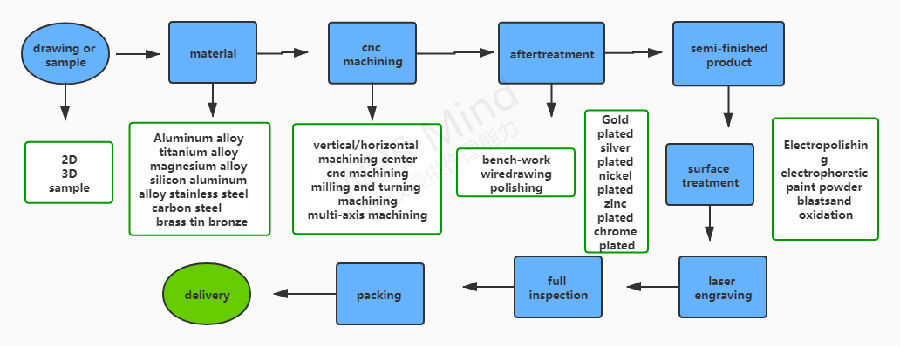

Product processing | CNC machining - full inspection - packaging - delivery |

Product standard | 5mm*40mm*100mm |

Surface treatment | Nature color |

Packing standard | Copy paper +pearl wool +carton box or according to customer requirements |

Related testing equipment | Calipers, projectors, two - dimensional height gauges, thread gauges, etc |

Flow chart of product implementation:

SWKD has rich experience in optical communication shell, panel and other outsell parts, and have been processing high silicon aluminum, oxygen free copper, cutting alloy and other materials for a long time.